Atmospheric Water Generation

Commercial

GENAQ Stratus generators are designed in dispenser format to supply the purest water to offices, public use facilities, hotels, restaurants, homes, etc. Get rid of bottled water and generate your own water, free of chemicals and in a sustainable way.

Stratus by GENAQ

Stratus S20

Coming soon

Stratus S50

Generation: 52 l/day

Consumption: 0.39 kWh/l

Power: 0.9 kW

Stratus S200

Generation: 202 l/day

Consumption: 0.19 kWh/l

Power: 1.6 kW

Industrial

GENAQ Nimbus range ensures pure drinking water supply for the industrial sector and remote locations like power plants, mines, oil rigs, or construction sites. Become autonomous and forget about logistics and installations in your premises.

Nimbus by GENAQ

Nimbus N500

Generation: 506 l/day

Consumption: 0.24 kWh/l

Power: 5.1 kW

Nimbus N4500

Generation: 4,445 l/day

Consumption: 0.22 kWh/l

Power: 40.8 kW

Emergencies

GENAQ Cumulus generators are designed with reinforced structure and portability features, to supply high quality drinking water in emergency situations, natural disasters, humanitarian aid, civilian and military camps, etc. Became independent from any uncontrolled water source.

Cumulus by GENAQ

Cumulus C50

Generation: 52 l/day

Consumption: 0.42 kWh/l

Power: 1 kW

Cumulus C500

Generation: 502 l/day

Consumption: 0.26 kWh/l

Power: 5.5 kW

Cumulus C5000

Generation: 5,091 l/day

Consumption: 0.26 kWh/l

Power: 50.2 kW

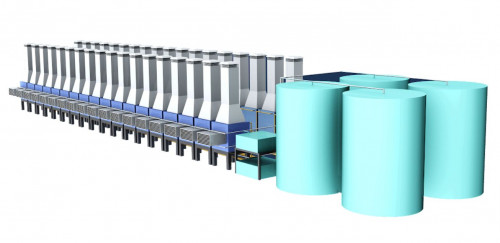

Large Scale

For larger water needs, GENAQ AWGplant is the air to water solution for both lower investment and operating cost per liter. A customized project to supply water for industrial processes, bottling plants, residential water supply, etc.

AWGplant by GENAQ